SCADA: IoT Connectivity, Benefits & Cyber Threats

April 13, 2024The integration of Supervisory Control and Data Acquisition (SCADA) systems with the Internet of Things (IoT) and Industrial Internet of Things (IIoT) represents a significant evolution in industrial automation and control. SCADA systems have long been the backbone of monitoring and managing industrial processes across various sectors, providing real-time data acquisition, control, and visualization. With the advent of IoT and IIoT technologies, SCADA systems have undergone transformative changes, enabling enhanced connectivity, scalability, and efficiency in industrial operations.

This integration brings the capabilities of SCADA systems, which excel in centralized monitoring and control, with the vast network of interconnected devices and sensors offered by IoT and IIoT.

This review will explore the integration of SCADA with IoT and IIoT, the difference between SCADA vs. IoT platforms, and the essentials for understanding the future of industrial automation it presents.

What is SCADA?

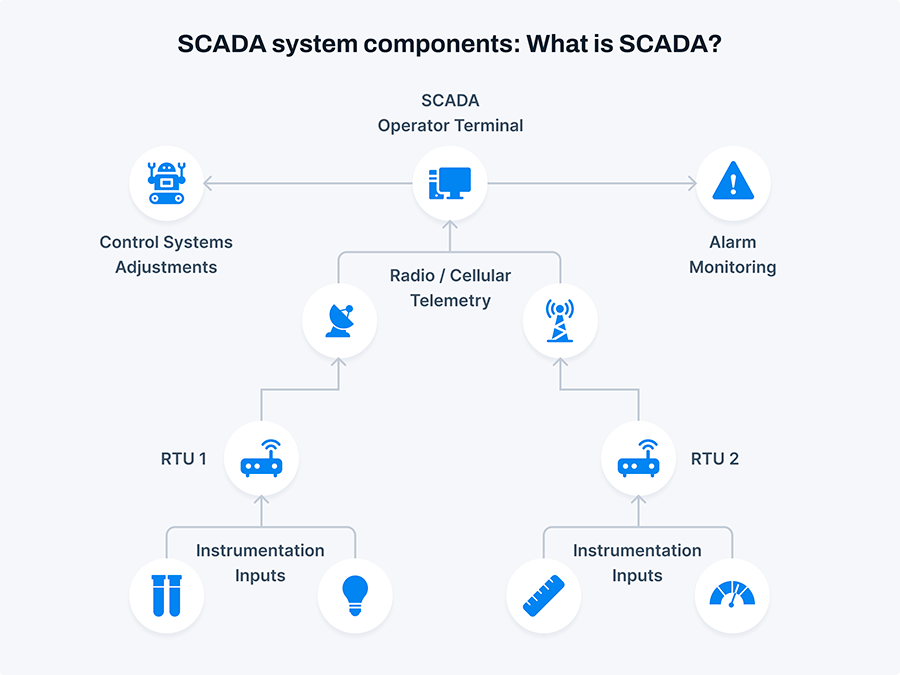

SCADA systems have been invaluable in helping us manage and regulate different operations such as oil and gas, mining, utilities, and power. At last, they were using proprietary technology such as mainframe computers and remote terminal units (RTUs) to access the data from the field sensors or transmit it to a central control center for processing and action. Over time, industrial computer systems with their control operation attributes such as computer networks and graphical interfaces were introduced.

Implementing programmable logic controllers (PLCs) caused improvement in the previous SCADA systems, allowing local data processing and execution of action commands without being interactive with the main station. The switch to TCP/IP protocol brought standardization of communications with the remote units and enhanced interoperability. SCADA technologies, which used to be largely related to the industrial segment, also acquired intruders from areas such as power and transport entities.

From 1990 onwards, an integrated SCADA system with a corporate network was introduced to facilitate the management’s ability to control the process parameters for making informed decisions. However, after gaining the attention of cyber attacks on the SCADA system, a lack of security is now becoming a significant shortcoming.

Benefits of SCADA systems

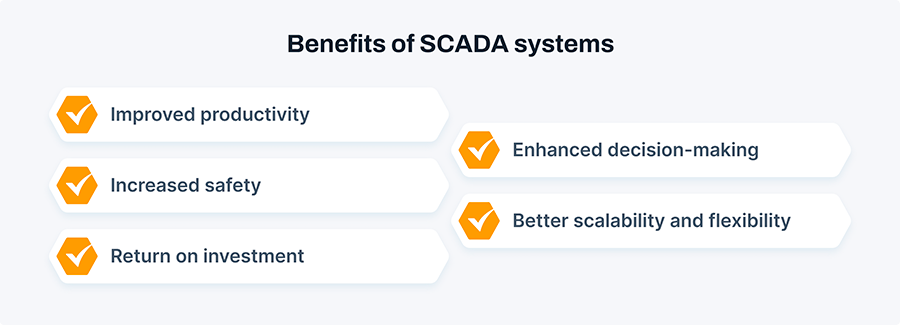

SCADA system integration offers numerous benefits for businesses across various industries. These benefits collectively contribute to operational efficiency, improved decision-making capabilities, enhanced safety measures, scalability, flexibility, cost savings, and a strong return on investment for businesses integrating SCADA systems into their operations.

Improved productivity

It automates processes, allowing employees to focus on critical tasks, monitor operations in real-time, and make adjustments for optimized processes, leading to increased productivity and cost savings.

Enhanced decision-making

SCADA systems provide real-time data insights from various sources, enabling informed decisions like identifying bottlenecks, optimizing production runs, and reducing downtime.

Increased safety

By monitoring equipment and processes in real-time, SCADA systems help identify safety hazards early and provide automatic alerts for quick corrective actions, thus enhancing safety and reducing risks.

Scalability and flexibility

These systems are highly scalable and flexible, making them suitable for businesses of all sizes. They can be customized to meet specific needs and integrated with other systems like enterprise resource planning (ERP) and customer relation management (CRM), providing a comprehensive solution that grows with the business.

Return on investment (ROI)

Automation through SCADA systems reduces costs, increases profitability, identifies areas for improvement, and optimizes operations, leading to significant cost savings and productivity gains. The average payback period for a SCADA system is less than two years.

SCADA with IoT and IIoT implementation

Integrating SCADA systems with IoT and IIoT technologies represents a significant advancement in industrial automation. SCADA systems traditionally oversee and manage critical infrastructure and industrial processes, such as manufacturing plants, power grids, and water treatment facilities. By incorporating IoT and IIoT capabilities, these systems gain enhanced functionality, efficiency, and insights into operations.

SCADA and IoT

Integrated with IoT, SCADA systems represent the forefront of automation, seamlessly syncing with smart systems to evolve operational workflows and decision-making processes. This integration covers a horizon shift in data gathering and analysis capacities. As a result, competing businesses get a chance to possess timely insights from a wide range of IoT devices and sensors. Merging SCADA's monitoring and control features with the data-amenable environment enabled by IoT will help elevate automation and lead to instantaneous data decision-making depending on the comprehensive, real-time data domain.

Additionally, the telemetry architecture joining SCADA with IoT enables the introduction of a novel trait of scalability and flexibility in system design. These integrations demand immediate upgrading to avoid inefficientness-of-obsolete-devices and to adapt to rapid change. The important strategic benefit that integration will present is enhanced security measures, which will feature remote monitoring capabilities, anomaly detection, and secure data transfer protocols that can guarantee robust protection against possible security breaches.

SCADA and Industrial IoT

SCADA is an integral and important system for controlling and monitoring methods in the industrial area. SCADA systems typically include highly intelligent but limited analytics components. Most commonly, they utilize their internal protocol communication with devices and border cases where they intersect with external systems. The SCADA system is successful in an environment with a scalar scalability level.

IIoT systems' adaptability allows them to cater to as many devices as needed. Furthermore, the information provided by IIoT systems is accessible no matter your location, and through cloud platforms, it becomes possible to create a strong business environment where you can make informed business decisions.

Looking forward, SCADA and IIoT capabilities steadily emerge as the most prominent technologies. SCADA enhances monitoring and control capabilities, supporting IIoT systems in smart cities. While the IIoT depends on the SCADA systems to get the data from there, it also uses a variety of analyses and intelligence through the implementation of the most advanced processing technologies.

Cyberthreats to SCADA with IoT connection

Within SCADA systems, the foundational control systems are known as Industrial Control Systems (ICS). They deal with the management of machinery and equipment in different industries, including oil and gas, utilities, and manufacturing. For the same reason, industrial IoT networks are expanding very rapidly across all of the market sectors.

Critical sectors take care of the oil and gas industries, electric power firms, banks, and internet service providers that are victims of a wide range of cyber dangers. The following types of hacker groups demand ransom for their work, competitors acting as either industrial spies or cyber-attacking opponents, and nation-states aiming to gain total control of production management tools and sensitive equipment.

One of the major weaknesses, however, is that industrial control systems intrinsically attract adversaries' audacity. The number of reported vulnerabilities in SCADA systems is increasing yearly, with approximately 89% of attacks being network exploits that severely impact system availability. On average, between 47 and 467 SCADA vulnerabilities are identified annually, as reported by Trend Micro.

The commonality of the loopholes in IoT devices is further aggravated by the fact that the architectures are not tested, and there are nonstandardized practices, which provide hackers with a variety of ways of breaching cybersecurity measures.

Attackers use different techniques, and the most common of them are online intrusion, mail spear-phishing, and distribution of trojan malware through infected USB sticks.

The difference between SCADA and IoT platforms

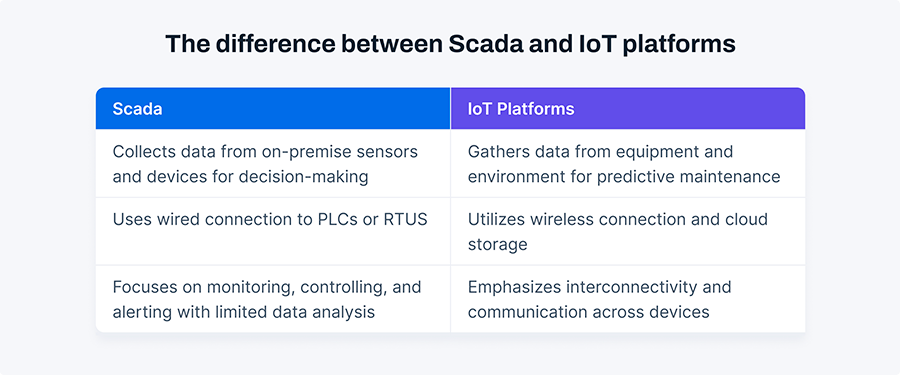

The fundamental difference between SCADA systems and IoT lies in their approach to data collection, processing, and system architecture.

SCADA Systems

- Data collection: SCADA systems are designed to collect data from sensors and devices on-premise for real-time decision-making, focusing on equipment status like speed and state to notify overseers of irregularities within the infrastructure.

- Architecture: SCADA systems traditionally use wired connections to programmable logic controllers (PLCs) or remote terminal units (RTUs) for data collection and processing within the factory, with limited data storage capabilities and a focus on real-time operations.

- Functionality: SCADA systems are tailored for monitoring, control, and alerting, providing good visibility and control over real-time operations but lacking extensive data analysis capabilities beyond real-time monitoring.

IoT platforms

- Data collection: IoT platforms utilize wireless database connections to store data on-premise or in the cloud, collecting diverse data from equipment, environment, submeter, and more for predictive maintenance and autonomous decision-making, enabling data analysis and insights beyond real-time monitoring.

- Architecture: IoT platforms leverage open internet protocols to translate machine languages into standardized formats, enhancing data governance, reliability, and accessibility for improved data analysis and scalability through a serverless architecture.

- Functionality: IoT platforms focus on interconnectivity, communication across devices regardless of manufacturer or model, and data analysis for predictive maintenance, optimization, and performance improvement, offering a broader scope of data collection and analysis compared to SCADA systems.

While SCADA systems excel at real-time monitoring, control, and alerting within a limited data scope, IoT platforms offer a more comprehensive approach to data collection, analysis, and system scalability, enabling predictive maintenance, data-driven decision-making, and enhanced interconnectivity across devices and systems.

Conclusion

However, the future seems like a promising place where SCADA merging into IIoT will be one of the major ways of industrial automation and smart city operation. This expansion will generate additional monitoring, control, and predictive maintenance options. Consequently, operational efficiency will increase, reducing downtime and optimizing resource utilization.

Industrial assets and secure data are key parts of this interconnected environment. Reliable cybersecurity measures should be the cornerstone of its protection. Integrating the SCADA system with the IoT and IIoT is worth giving a thought. Organizations can harness the full potential of integrating SCADA with IoT and IIoT, ensuring a dual progression of innovation and sustainability across a multitude of areas.